OpenAI’s ChatGPT, along with other large language models, has demonstrated remarkable abilities in natural language understanding and generation. Engaging in conversations with these models can be astonishingly human-like. As a technology company that makes artificial intelligence for industrial robots, Micropsi Industries is naturally compelled to consider how ChatGPT could be used for robotics applications. To us, while ChatGPT represents a significant innovation, one shouldn’t overestimate its capabilities in the manufacturing space, at least not yet.

Thinking and problem-solving in manufacturing require a level of physicality and specialization that language models alone can’t provide. Instead, the future of production lies in developing AI systems that can learn from real-world data, adapt to specific tasks, and generalize their knowledge across similar domains.

A critical lesson from AI research, often in collaboration with cognitive science, is that thinking is not a single, coherent skill. Being good at arithmetic does not mean that you can write a well-reasoned text. Playing chess superhumanly does not imply an ability to think beyond that.

ChatGPT's capacity to talk and program, while valuable, does not encompass all aspects of intelligent behavior. Equating the capabilities of computers and humans based solely on their conversational abilities is a flawed analogy. The thinking needed to plan and execute complex manufacturing processes comprises a multitude of skills beyond language processing.

Specialization doesn't occur by contemplating a subject at an abstract level. In manufacturing, you don't learn how to work with metal by pondering it deeply; you learn it by using a file. The knowledge required to manipulate metal involves muscle movements and sensory feedback that can’t be encapsulated in language alone.

This phenomenon aligns with the concept of embodiment, which holds that thinking relies on the body to understand the meanings of words. AI models that lack a physical presence are akin to what we might call bluffers in humans. Even though they know how to convincingly talk about something they've heard of, they lack the experiential knowledge to substantiate their claims.

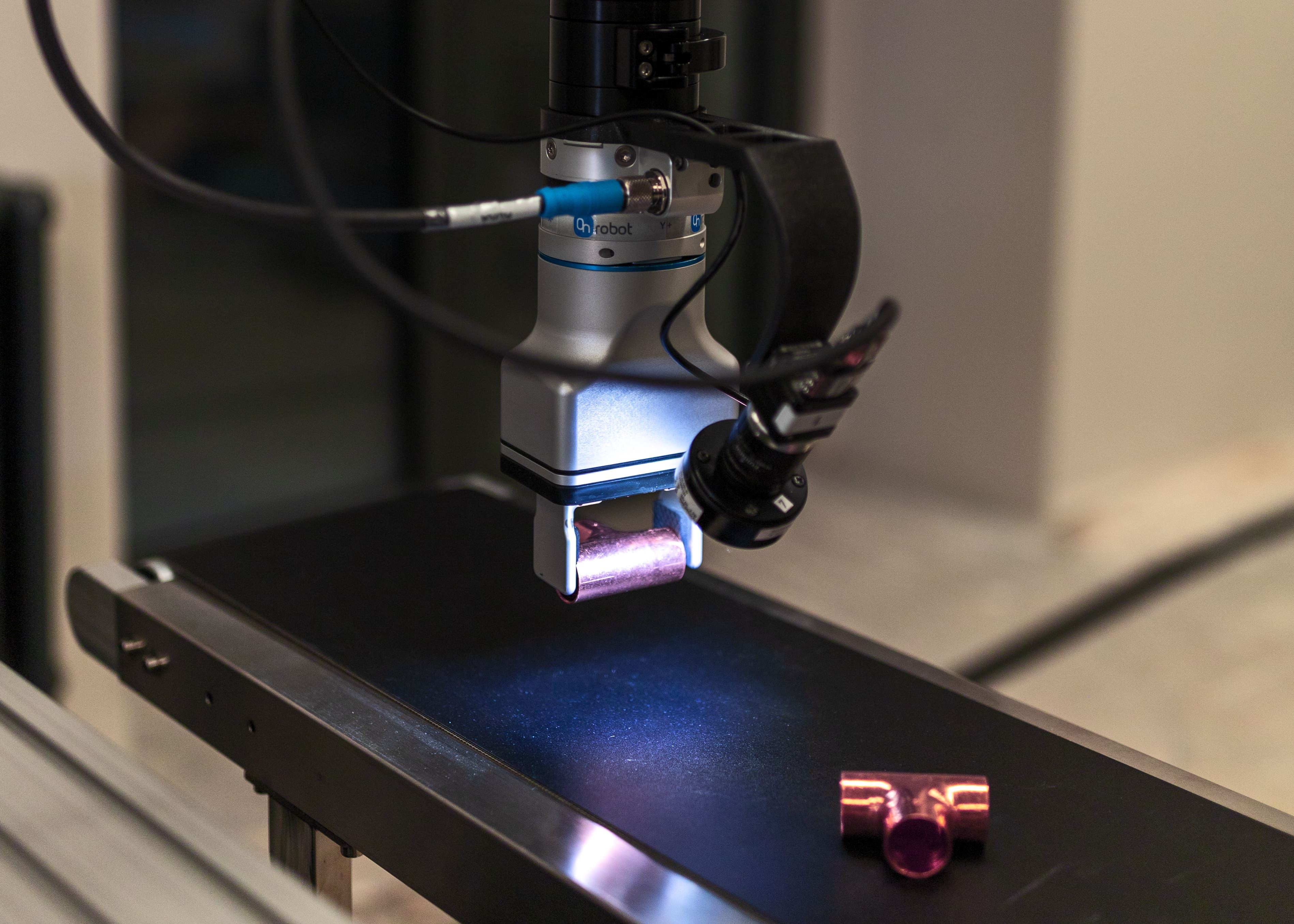

To do production, AI models require physicality to perform tasks. Training an AI-guided robot to carry out a manufacturing task must take place on site, with the right tool, with the right material, under real conditions. ChatGPT and other large language models can only operate within the boundaries of the data used for training. An AI for manufacturing, in contrast, must be built from production data and information about the products being manufactured.

At the same time, even specialized production AI has limitations imposed by available hardware. An AI-guided robot can theoretically learn to do operations that involve delicate manipulation, such as a human worker turning a workpiece with their fingers. The trouble is that the hardware for such applications is often too expensive, too fragile, or too inflexible.

Still, where human dexterity is not essential yet human adaptability is, AI can come in. Robots driven by AI can handle tasks like quality control, cable handling, or assembly; these require precision but don't always follow identical sequences. While data for such processes exists, it's not readily available in language on the internet. Reading about these processes won't suffice. They must be learned through practical experience.

There is no off-the-shelf AI that can be connected to a robot and enable that robot to immediately assemble an unknown component. Handling unique workpieces often requires practice, even for humans. Unlike humans, though, AI can learn almost indefinitely and is easy to reproduce. To develop AI systems that can handle a wider range of tasks, we need to expand their capabilities by incorporating more data.

The path to a production AI that can truly transfer motion knowledge between different use cases is likely to be through islands of generalization. For example, once many individual cable-handling tasks have been trained, the similarities become apparent to the algorithm and allow generalization. ChatGPT, however, can’t talk its way to successfully train and handle a different task. Just because you can talk the talk doesn’t mean you can walk the walk.

So while ChatGPT and similar language models may represent remarkable advances in AI, they’re not the sole keys to revolutionizing production.

Want to learn how AI can help you automate tasks otherwise considered too complex to automate? Get in touch now.

Using MIRAI, we have solved a challenge we could not solve with standard automation technologies. Accuracy, and performance KPIs have been reached, imprving productivity and quality.

%20(1)%202.webp)

%20(1)%202.webp)

Sed viverra ipsum nunc aliquet bibendum. Sit amet nisl suscipit adipiscing bibendum est. Urna nunc id cursus metus aliquam eleifend. Sed risus pretium quam vulputate dignissim suspendisse in est ante. Tempor commodo ullamcorper a lacus vestibulum sed arcu non odio. Integer eget aliquet nibh praesent tristique magna sit. Orci phasellus egestas tellus rutrum tellus pellentesque eu. Pharetra massa massa ultricies mi quis hendrerit dolor magna eget. Dui vivamus arcu felis bibendum.

Sed viverra ipsum nunc aliquet bibendum. Sit amet nisl suscipit adipiscing bibendum est. Urna nunc id cursus metus aliquam eleifend. Sed risus pretium quam vulputate dignissim suspendisse in est ante. Tempor commodo ullamcorper a lacus vestibulum sed arcu non odio. Integer eget aliquet nibh praesent tristique magna sit. Orci phasellus egestas tellus rutrum tellus pellentesque eu. Pharetra massa massa ultricies mi quis hendrerit dolor magna eget. Dui vivamus arcu felis bibendum.

%20(1)%202.webp)

%20(1)%202.webp)